Description

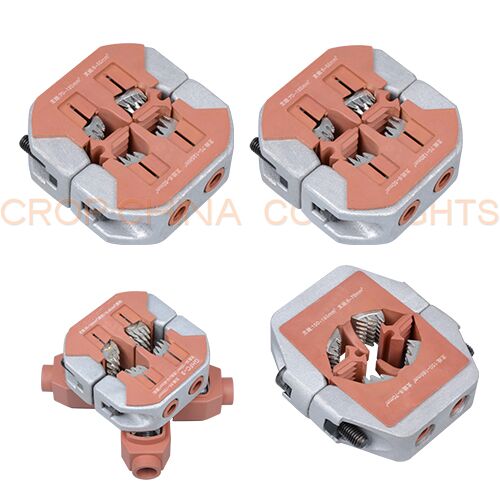

Insulation piercing multi-core connectors /multi-core ring connectors

Description of Insulation piercing multi-core connectors

Insulation piercing multi-core connectors also named multi-core ring connector.The cable ring type connector is used for simple and reliable installation while ensuring maximum safety during life line work.The Insulation piercing multi-core connectors can be used for stranded and solid aluminum or copper conductors.It also can be used for the cable with PVC or XLPE insulation.

4 core or 3 1/2 core ring type tap off connector with IP2X protection and piercing retardant system.

On the connector ring is pressembled on the main conductor the plastic housing offer full protection against touching live contact teeth(finger test),test to EN 60529.During pressembly on the main conductor the contact protection system detects early contact teeth via the predetermined breaking point to ensure a large operational safety during tap off conductor assembly.

Material of multi-core ring connectors

Body: High strength aluminum alloy (AIMgSi)

Contact segment: corrosion resistant,Contacts in brass (Cu Zn),electro tinned

insulation parts: glassfiber reinforced PA

Bolt: steel,grade 8.8.

| Type | Sector Conductor | Round Conductor | Reference Torque | ||

| Main (mm2) | Tap (mm2) | Main (mm2) | Tap (mm2) | ||

| UTC-1 | SM/SE 70-95 | SM/SE 6-50 | RM/RE 70-95 | RM/RE 6-70 | 15Nm |

| UTC-2 | SM/SE 95-150 | SM/SE 6-50 | RM/RE 95-150 | RM/RE 6-70 | 15Nm |

| UTC-3 | SM/SE 95-150 | SM/SE 6-150 | RM/RE 95-150 | RM/RE 6-150 | 15Nm |

| UTC-4 | SM/SE 185-240 | SM/SE 6-50 | RM/RE 185-240 | RM/RE 6-70 | 20Nm |

Conductors types:

sm: Sector stranded. se: Sector solid.rm: Round stranded re: Round solid

Related Product

Installation of multi-core ring connectors

Step 1: Cable over sheath is removed and the core separators placed between the cores.

Step 2: The two connector halves positioned over the cores and the bolts slightly tightened.

Step 3: Stripped ends of branch cores inserted in the branch channels and the bolts are tightened.

Step 4: The connector halves are closed by tightening the two outer bolts while the contact segments pierce the main cable cores.

Step 5: The outer metal ring is at all times insulated from the life conductors.