Description

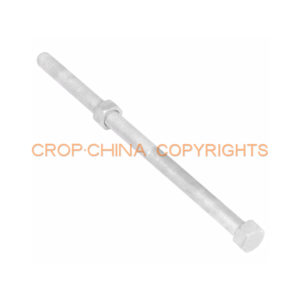

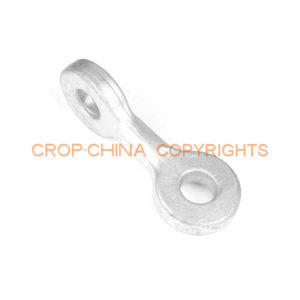

OVAL EYE BOLT

Description

Produced in Steel Q235, hot dip galvanized according to ASTM A-153, BS729, ISO1461.

Furnished with 1 square nut.

| Type | Dimensions in inches and millimeters | |||

| C | D | L | T | |

| OEB01 | 1 1/2″(38) | 5/8″(16) | 6″(150) | 4″(100) |

| OEB02 | 1 1/2″(38) | 5/8″(16) | 8″(200) | 4″(100) |

| OEB03 | 1 1/2″(38) | 5/8″(16) | 9″(230) | 4″(100) |

| OEB04 | 1 1/2″(38) | 5/8″(16) | 10″(250) | 6″(150) |

| OEB05 | 1 1/2″(38) | 5/8″(16) | 12″(300) | 6″(150) |

| OEB06 | 1 1/2″(38) | 5/8″(16) | 14″(350) | 6″(150) |

| OEB07 | 1 1/2″(38) | 5/8″(16) | 16″(400) | 6″(150) |

| OEB08 | 1 1/2″(38) | 5/8″(16) | 18″(450) | 6″(150) |

| OEB09 | 1 1/2″(38) | 5/8″(16) | 20″(500) | 6″(150) |

| OEB10 | 1 1/2″(38) | 5/8″(16) | 22″(550) | 6″(150) |

| OEB11 | 1 1/2″(38) | 5/8″(16) | 24″(600) | 6″(150) |

| OEB12 | 1 1/2″(38) | 5/8″(16) | 6″(150) | 6″(150) |

| OEB13 | 1 1/2″(38) | 3/4″(20) | 8″(200) | 6″(150) |

| OEB14 | 1 1/2″(38) | 3/4″(20) | 9″(230) | 6″(150) |

| OEB15 | 1 1/2″(38) | 3/4″(20) | 10″(250) | 6″(150) |

| OEB16 | 1 1/2″(38) | 3/4″(20) | 12″(300) | 6″(150) |

| OEB17 | 1 1/2″(38) | 3/4″(20) | 14″(350) | 6″(150) |

| OEB18 | 1 1/2″(38) | 3/4″(20) | 16″(400) | 6″(150) |

| OEB19 | 1 1/2″(38) | 3/4″(20) | 18″(450) | 6″(150) |

| OEB20 | 1 1/2″(38) | 3/4″(20) | 20″(500) | 6″(150) |

| OEB21 | 1 1/2″(38) | 3/4″(20) | 22″(550) | 6″(150) |

| OEB22 | 1 1/2″(38) | 3/4″(20) | 24″(600) | 6″(150) |

*Note: this bolt has Chamfering type, if you need this type, pls explain when you place an order.

CROP Pole Line Hardware is designed and manufactured primarily from specially selected steel,

or ductile/malleable iron castings with chemical and physical properties most suitable for product performance and applications in which they are used. In addition, CROP also manufactures products from various types of materials including wood, aluminum and plastic alloys – such as our nylon alloy insulator threads on forged steel crossarm pins. CROP products are engineered for strength, reliability, durability and ease of installation. Our modern, efficient production equipment and rigid quality control standards assure that CROP hardware is consistently of the highest obtainable quality.