Description

Description of Noninsulated crimp terminals

Noninsulated crimp terminals are also named crimp terminals or wire connector.They are used to terminate stranded wires. Noninsulated crimp terminals is made of tin plated copper,uninsulated ferrules are designed to form neat end terminations to multi-strand cables or wires. Smooth funnel entry assists in wire insertion. Crimp terminals specifically designed to aid in termination of extra flexible fine stranded conductor,provides enhanced flexibility relating to wire termination and management.A positive contact surface helps ensure system integrity.

Material of crimp terminals

Tin plated copper

Features of wire connector

1.Seamless barrels

2.Smooth funnel entry to make wire insertion easie

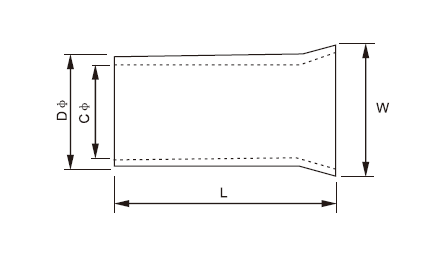

Product picture of terminals

| Item No. | Conductor section | |||||

|---|---|---|---|---|---|---|

| A.W.G | mm2 | C | D | L | W | |

| EN 0306 | 24 | 0.3 | 0.8 | 1.1 | 6 | 1.5 |

| EN 0308 | 8 | |||||

| EN 0505 | 22 | 0.5 | 1 | 1.3 | 5 | 1.7 |

| EN 0506 | 6 | |||||

| EN 0508 | 8 | |||||

| EN 0510 | 10 | |||||

| EN 0512 | 12 | |||||

| EN 7506 | 20 | 0.75 | 1.2 | 1.5 | 6 | 1.9 |

| EN 7508 | 8 | |||||

| EN 7510 | 10 | |||||

| EN 7512 | 12 | |||||

| EN 7515 | 15 | |||||

| EN 1006 | 18 | 1 | 1.4 | 1.7 | 6 | 2.2 |

| EN 1008 | 8 | |||||

| EN 1010 | 10 | |||||

| EN 1012 | 12 | |||||

| EN 1015 | 15 | |||||

| EN 1018 | 18 | |||||

| EN 1020 | 20 | |||||

| EN 1506 | 16 | 1.5 | 1.7 | 2.0 | 6 | 2.5 |

| EN 1507 | 7 | |||||

| EN 1508 | 8 | |||||

| EN 1510 | 10 | |||||

| EN 1512 | 12 | |||||

| EN 1515 | 15 | |||||

| EN 1518 | 18 | |||||

| EN 2506 | 14 | 2.5 | 2.3 | 2.6 | 6 | 3.3 |

| EN 2507 | 7 | |||||

| EN 2508 | 8 | |||||

| EN 2510 | 10 | |||||

| EN 2512 | 12 | |||||

| EN 2515 | 15 | |||||

| EN 2518 | 18 | |||||

| EN 4009 | 12 | 4 | 2.8 | 3.2 | 9 | 3.9 |

| EN 4010 | 10 | |||||

| EN 4012 | 12 | |||||

| EN 4015 | 15 | |||||

| EN 4018 | 18 | |||||

| EN 4020 | 20 | |||||

| EN 6006 | 10 | 6 | 3.5 | 3.9 | 6 | 4.7 |

| EN 6010 | 10 | |||||

| EN 6012 | 12 | |||||

| EN 6015 | 15 | |||||

| EN 6018 | 18 | |||||

| EN 10-12 | 8 | 10 | 4.5 | 4.9 | 12 | 5.8 |

| EN 10-15 | 15 | |||||

| EN 10-16 | 16 | |||||

| EN 10-18 | 18 | |||||

| EN 10-20 | 20 | |||||

| EN 16-12 | 6 | 16 | 5.8 | 6.2 | 12 | 7.2 |

| EN 16-15 | 15 | |||||

| EN 16-16 | 16 | |||||

| EN 16-18 | 18 | |||||

| EN 16-20 | 20 | |||||

| EN 16-22 | 22 | |||||

| EN 16-25 | 25 | |||||

| EN 16-30 | 30 | |||||

| EN 25-12 | 4 | 25 | 7.5 | 7.9 | 12 | 9.1 |

| EN 25-15 | 15 | |||||

| EN 25-16 | 16 | |||||

| EN 25-18 | 18 | |||||

| EN 25-20 | 20 | |||||

| EN 25-22 | 22 | |||||

| EN 25-25 | 25 | |||||

| EN 25-30 | 30 | |||||

| EN 35-12 | 2 | 35 | 8.3 | 8.7 | 12 | 10.2 |

| EN 35-15 | 15 | |||||

| EN 35-16 | 16 | |||||

| EN 35-18 | 18 | |||||

| EN 35-20 | 20 | |||||

| EN 35-22 | 22 | |||||

| EN 35-25 | 25 | |||||

| EN 35-30 | 30 | |||||

| EN 50-20 | 1/0 | 50 | 10.3 | 10.9 | 20 | 12.7 |

| EN 50-22 | 22 | |||||

| EN 50-25 | 25 | |||||

| EN 50-30 | 30 | |||||

| EN 70-20 | 2/0 | 70 | 13.5 | 14.3 | 20 | 15.8 |

| EN 70-22 | 22 | |||||

| EN 70-25 | 25 | |||||

| EN 70-30 | 30 | |||||

| EN 95-25 | 3/0 | 95 | 14.8 | 15.6 | 25 | 17.3 |

| EN 95-30 | 30 | |||||

| EN 95-32 | 32 | |||||

| EN 120-30 | 4/0 | 120 | 16.7 | 17.7 | 30 | 20.2 |

| EN 120-32 | 32 | |||||

| EN 120-34 | 34 | |||||

| EN 120-38 | 38 | |||||

| EN 150-34 | 34 | |||||

| EN 150-38 | 38 | |||||

| EN 150-40 | 40 | |||||

Related Product