5 TIPS FOR PURCHASING INSULATION PIERCING CONNECTOR

Do you encounter such a problem when purchasing insulation piercing connector: How can you buy a good quality and price competitive insulation piercing connector? To solve this problem, you need have a full understanding of the insulation piercing connector (IPC connector), and then you can know how to purchase a cost effective insulation piercing connector. Next, I will take you a comprehensive understanding of insulation piercing connector from the following aspects, and provide 5 tips for purchasing insulation piercing connector.

What is insulation piercing connector(IPC connector)?

Insulation piercing connector (IPC connector) is mainly composed of reinforced plastic cover, metal blades,waterproof sealing , silicone grease, high-strength bolt, shear head and end cap, Insulation piercing connector used to make connection between protected low voltage overhead lines (with neutral), transformers downspout or service drop cable.

When the cable needs to be branched or connected, insert the terminal of the cable branch line into the waterproof terminal cap cover. After determining the branch position of the main line, use a socket wrench to twist the torque nut on the clamp. The contact blade will pierce the cable insulation layer during the process. In contact with the conductor, the gasket presses around the punctured position of the cable, and the silicone grease in the shell overflows. When the torque reaches the set value, the nut torque mechanism falls off, the main line and the branch line are connected, and the waterproof performance and electrical effect reach the standard The required parameters.

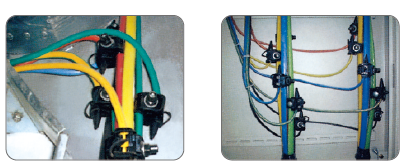

It can be used in high-rise buildings, civil buildings, street light distribution systems, outdoor overhead lines and other low-voltage power circuits and lighting distribution lines.

Installation temperature:-10℃-+60℃

Standard: IEC 61284, EN 50483, IRAM2435, NFC33 020.

Advantage of insulation piercing connector

- Easy installation, low cost, safe and reliable maintenance-free.The installation of the piercing connector can be installed with a suitable socket wrench.

- The cable branch can be made without cutting off the main cable or stripping the insulation layer of the cable. The piercing connector is completely insulated, and it can be live-operated.

- It can be branched at any position of the cable. There is no need to use terminal boxes and junction boxes.And the piercing connector is resistant to distortion, shockproof, waterproof, anti-corrosion and aging.

- The use of insulation piercing clamps for cable branching has obvious comprehensive benefits and is more cost-effective than the previous traditional connection methods.

- Stable electrical performance.

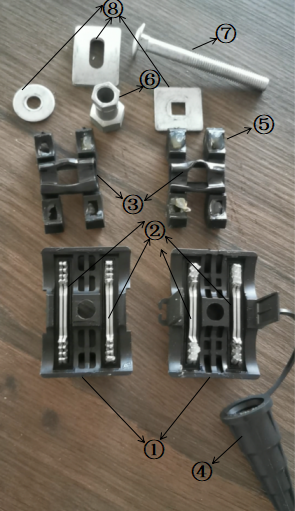

The internal structure of the Insulation piercing connector

① Plastic cover

The plastic cover is made of elastic reinforced engineering insulating material weather & UV resistance reinforced thermoplastic PA66.It can maintain good elasticity and strength even at high temperatures.

② metal blades

The metal blades is made of copper tinned,brass tinned or aluminum alloy.The copper tinned blades and brass tinned blades can be used for copper conductor and aluminum conductor.The aluminum alloy blades just can be used for aluminum conductor.The metal blades of the piercing connector (IPC connector) is corrosion resistance & can be proven in corrosion test.Connector blade teeth will be factory greased & sealed to retard water and moisture ingress & corrosion.It can ensure the best contact area on the wire, suitable for copper-aluminum transition.

③ Waterproof sealing

The waterproof sealing is made of rubber,it has a strong water resistance.

④ Cable end cap

The cable end cap of rubber,each insulation piercing connector is attached a cable end cap to the body.

⑤ Silicone grease

⑥ Shear head

The shear head of the insulation piercing connector designed after accurate force calculation, it is made of zinc alloy.when the optimal puncture force is tightened, the shear head will automatically fall off, thus avoiding the disadvantages of poor contact caused by excessive force transition and damage to the wire. The installation of each piercing connector is in the best state, ensuring the smallest contact resistance and the best thermal cycling state, which overcomes the instability of traditional connection methods.

⑦ Bolt

The bolt made of hot dip galvanized ,it is allow safe Live-Line installation.the bolts is shear Head type so that it controls the effective applied Torque during installation & break off at a specified torque after establishing proper connection. It have strong rust and corrosion resistance.The hardness grade is 8.8 grade.

⑧ Washer: made of hot dip galvanized

Types of Insulation piercing connector (IPC connector)

1.Classified by voltage,insulation piercing connector can be divided into 1KV,10KV,20KV.

2.Classified by grounding or not grounding,insulation piercing connector can be divided into CRS series,CRSF series

3.Classified by appearance,insulation piercing connector can be divided into PCT13C series 1bolt,PCT24C series 2 bolt,JBC series 1bolt and 2 bolt,CRT series,PT series ,OEM series.

4.Classified by quality,it can be divided into normal quality and 6KV underwater quality

5.Classified by bare conductor and insulated ,it can be divided into PCT13C series and PCT13CB series.

6.OEM type.According to customer’s drawing or sample to produce.

Performance test of Insulation piercing connector

1.Corrosion Qualification Test

The total test should include four identical periods of 14 days, in which 7 days of exposure in Saline environment & in other 7 days – 8 hrs cycles in SO2 environment & 16 hrs in laboratory environment.

2.Electrical Ageing Test

3.Underwater High Voltage Test

The tightening of the connectors should be at minimal value of the torque indicated by the manufacturer. The sample should be placed in tank full of water on 30cm height. After an immersion for 30mins, the immersed connector is subjected to a

dielectric test under a voltage of 6KV at industrial frequency during 1 min. No flash over/ breakdown should occur at 6KV during 1 min, for ±10 mA Leakage current setting.

4.Mechanical Tests

For checking electrical continuity, shear heads & mechanical behaviour of the connector’s suitable tests as per the above specification.

Insulation piercing connector installation

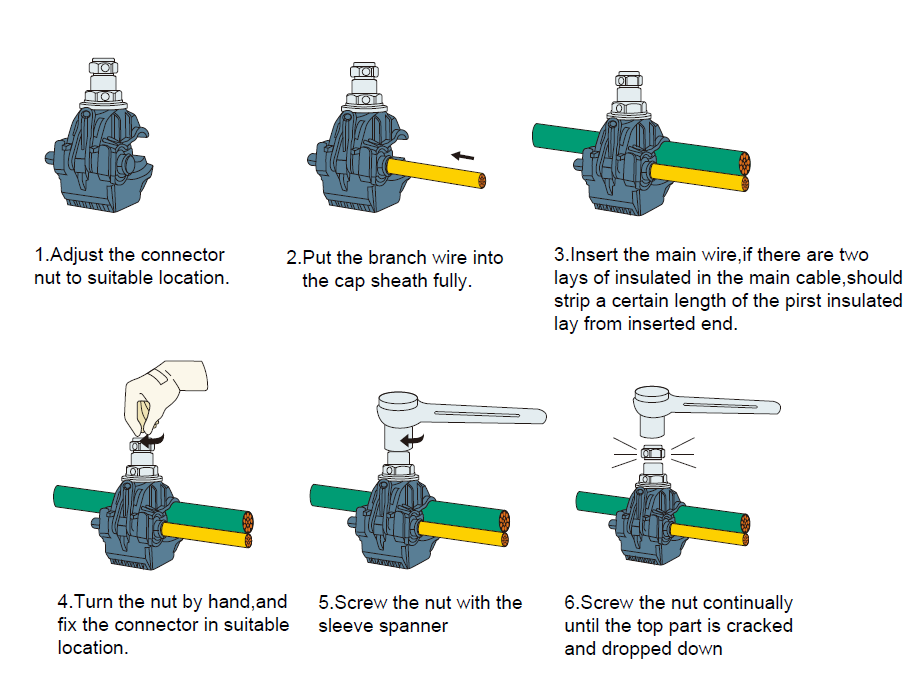

One bolt insulation piercing connector installation demo

Requirement material:

one piece copper tinned one bolt insulation piercing connector

1 piece main conductor 70mm2,1 piece tap conductor 20mm2

1 piece socket wrench.

Installation step:

1.Adjust the nut of insulation piercing connector to a suitable position.

2.Put the branch conductor fully insert into the cable end cap.

3.Insert the main conductor. If the main line cable has two layers of insulation, strip off the first insulation layer at the insertion end to a certain length.

4.Tighten the nut by hand first, and fix the insulation piercing connector in the proper position.

5.Tighten the nut with a socket wrench of the corresponding size.

6.Continue to tighten the nut until the shear head breaks off and the installation is complete.

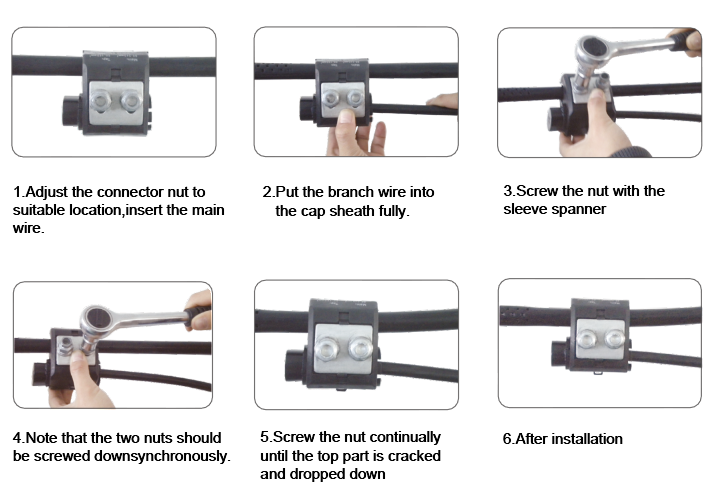

Two bolt insulation piercing connector installation demo

Requirement material:

1.one piece copper tinned 2 bolt insulation piercing connector

1 piece main conductor 70mm2,1 piece tap conductor 20mm2

1 piece socket wrench.

Installation step:

1.First unscrew the wire clamp and insert the main wire into the main wire groove. Do not twist the main wire with the knife ruler. Pay attention to whether the wire diameter range corresponds to this wire clamp.

2.Put the branch line into the branch line slot.

3.Tighten it with a socket wrench. It is strictly forbidden to use an open wrench.

4.Note that the two nuts should be screwed down synchronously at one time.

5.When tightened to a certain strength, the constant torque nut is broken.

Installation requirements for piercing connector

1.When stripping off the outer sheath of a multi-core cable, it is strictly forbidden to cut the insulation layer of the core. In case of damage, it should be dealt with in time according to the general cable insulation remedial specifications.

2.The stripping length of the jacket should not be greater than 50 times of the cable diameter, and the stripping length should be minimized while the installation is convenient.

3.The outer sheath of the single-core cable should also be stripped, but the stripping length is slightly larger than the width of the piercing clamp.

4After the outer sheath is stripped, the exposed cable dressing should be cut at the same time, and the two ports should be wrapped with insulating plastic tape, so that the filling dressing in the cable is not exposed.

5.In the hoistway where multiple cables are installed in parallel, the installation positions of multiple piercing clamps should not be on the same plane or elevation, and the distance of the cable outer diameter should be kept at least 3 times, and the installation positions should be staggered to reduce the accumulation of installation. volume.

6.Use No. 13 and No. 17 closed wrenches, glasses wrenches, and socket wrenches to tighten the torque nut of the piercing clamp until it falls off. Before the torque nut falls off, it is strictly forbidden to use open-end wrenches, adjustable wrenches, pliers, etc. to tighten the nuts. When encountering hard cable insulation, you can properly tighten the large nuts under the torque nut, subject to the non-fracturing clamp shell.

5 Tips for purchasing insulation piercing connector (IPC connector)

1.Confirm the material of conductor which used for insulation piercing connector before ordering.

Confirm the material of conductor is very important. Because if the conductor is aluminum conductor,you can use aluminum blade insulation piercing connector(IPC connector). The price of aluminum blade IPC connector is cheaper than copper tinned blades and brass tinned blades, You can save the costs,and purchase the suitable insulation piercing connector.

2.Confirm the conductor range.

Confirm the conductor range also important,if the range of conductor is incorrect,and your purchasing insulation piercing connector can’t connect,the loss is very serious.

3.Confirm the material of blades.

Confirm the material of the blade according to the material of the conductor. For copper conductor, you can choose the piercing connector with tinned copper blade or tinned brass blade piercing connector. The piercing connector with tinned copper blade has better performance than tinned brass blade, so the price is also a little expensive than tinned brass blade piercing connector.

4.Let the manufacturer provide sample testing before purchasing.

You can ask your favorite manufacturer to provide samples for you to test whether it meets your requirements before purchasing, and then arrange the purchase.

5.You can commission SGS or other testing agencies to test before delivery the goods.It can guarantee that you will received the goods meet your requirements.

Conclusion

After reading this article, you should have a more comprehensive understanding of piercing connector, whether you are a purchaser or a salesman,and will know the important point to purchase insulation piercing connector. If you have any questions, please feel free to contact me.I will tell you everything I know about insulation piercing connector.Email: [email protected], Mobile/Whatsapp/skype/Wechat: 008617757788662